Week 10 — Bio Production

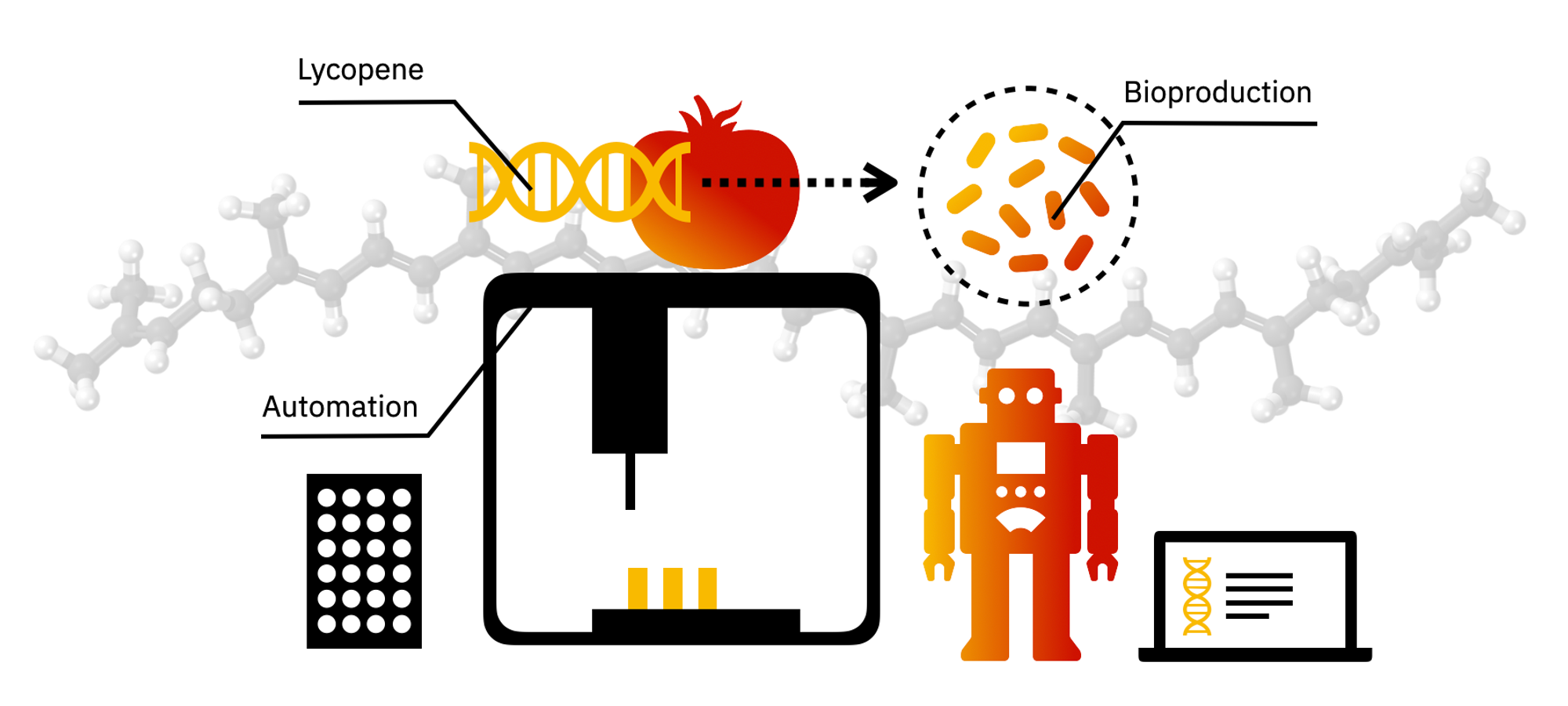

This week explores bio production—scaling from bench‑scale designs to strains and processes that produce carotenoids (e.g., lycopene, β‑carotene) and other biomolecules. Expect an emphasis on media design, carbon sources (e.g., fructose), and automation.

- Date: Tue Apr 8. Slides: Will be shared after class. Recording: Zoom

- Warning Part A is based on lecture prompts (Mandatory for Committed Listeners). Part B is based on the Bio Production Lab (Mandatory for Committed Listeners and MIT/Harvard students). Part A — Lecture Questions Assume that all of the molecular biology work you’d like to do could be automated. What new biological questions would you ask, or what new types of products would you make? If you could make metric tons of any protein, what would you make and what positive impact could you have? Part B — Lab‑Linked Questions Key Link:

- Date: Wed Apr 9. Slides: 2025: Lycopene & β‑Carotene Bioproduction Recording: Zoom

Tip This lab focuses on designing, ordering, and assembling DNA constructs that support your final project goals. Document Benchling files, provide FASTA sequences, and outline a precise cloning & validation plan.

- DNA Design 1.1 Benchling Documentation Workspace reference — include links or screenshots of your Benchling workspace. Plasmid maps & features — promoters, CDS, antibiotic markers, restriction sites. Rationale — explain element choices (host compatibility, reporter/assay match). 1.2 FASTA Files Submission‑ready sequences for each designed construct. Verify correctness via in‑silico digest or alignment. 1.3 Provider Requirements (e.g., Twist) Order summary — list fragments/constructs, lengths, GC content, constraints. Checklist — avoid problematic repeats/hairpins; remove restricted sites; check stop codons/frames. 2) Detailed Protocol 2.1 DNA Assembly and Cloning Overview — choose Gibson, Golden Gate, or restriction‑ligation as appropriate. Linearization/fragment prep — digest or PCR; purify. Assembly reaction — follow kit‑specific conditions (e.g., Gibson 50 °C for 15–60 min; Golden Gate cyclical 37 °C/16 °C). Transformation — competent cells; plate on appropriate antibiotic. Colony screening — colony PCR or miniprep → verification. 2.2 Reagents & Materials Assembly mixes (e.g., NEB Gibson/Golden Gate). Competent cells (e.g., DH5α, TOP10). LB‑Agar + antibiotic (Amp, Kan, etc.). Primers — 20–30 bp overlaps for Gibson or type IIS flanks for Golden Gate. 2.3 Useful Databases RCSB PDB UniProt

- Bio Production lab protocol — Google Doc Lycopene via fructose — Biotechnol Lett (2016) Fructose improves yield & expression — Biotechnol Prog (1999) Protein expression in E. coli — Frontiers in Microbiology (2021)